In today’s fast-moving supply chain landscape, order fulfillment plays a central role in shaping customer satisfaction, operational efficiency, and overall business success. It covers the complete journey of an order from the moment it is received to the instant it reaches the customer, making it a critical pillar of modern logistics.

As consumer expectations continue to rise, industries are shifting toward faster, more reliable, and highly coordinated delivery models. Understanding the order fulfillment process, its importance, and the best practices behind it has become essential for building efficient, resilient, and customer-centric supply chains.

What is Order Fulfillment?

Order fulfillment is the end-to-end process of receiving, processing, and delivering customer orders accurately and on time. It covers essential steps such as order confirmation, inventory allocation, picking, packing, shipping, and delivery. The process depends on coordinated systems and teams, supported by tools like Warehouse Management Systems, barcode scanning, automation, and real-time tracking to improve speed and reduce errors.

A strong order fulfillment process enhances customer satisfaction, builds brand trust, and lowers operational costs. By ensuring fast, accurate, and consistent deliveries, businesses can boost productivity and stay competitive in a market where customers expect quick and reliable service.

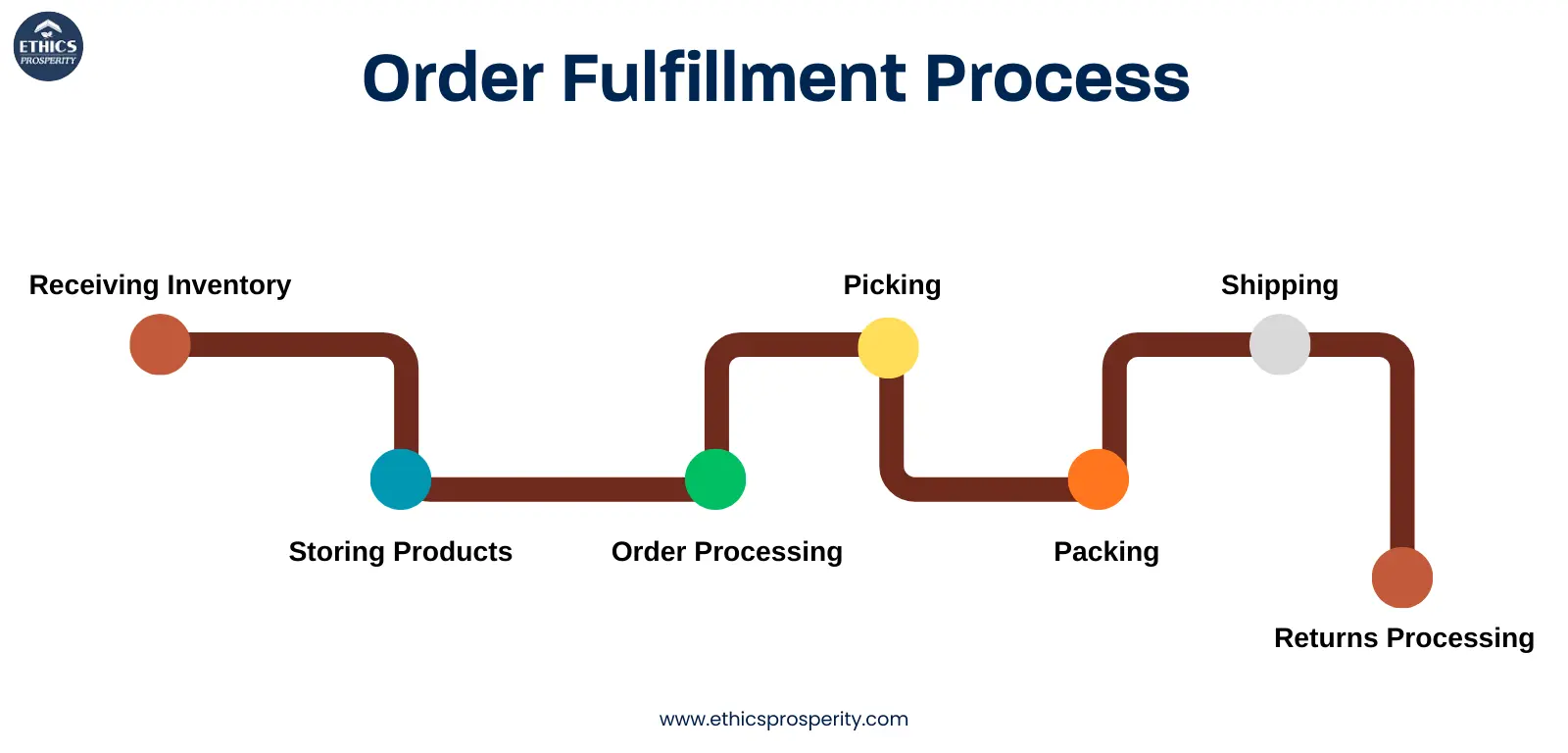

Order Fulfillment Process

Receiving, processing, and delivering customer orders are core parts of the order fulfillment process. While the workflow may vary by company, most businesses follow a similar set of common steps.

Receiving Inventory:

This step involves accepting incoming goods from suppliers, checking them for accuracy and quality, and updating inventory records. It ensures that the right products, in the right quantities and condition, are added to the warehouse stock before order processing begins.

Storing Products:

This step involves organizing and placing received goods in designated warehouse locations. Proper storage ensures easy accessibility, better inventory control, and faster picking when customer orders need to be fulfilled.

Order Processing:

This step includes verifying customer orders, checking inventory availability, and preparing items for picking and packing. Efficient order processing ensures accuracy and smooth movement of products through the fulfillment workflow.

Picking:

This step involves selecting the products from their storage locations based on the customer order. Accurate and organized picking is crucial to ensure the right items and quantities are prepared for packing and shipping.

Packing:

This step involves securely packaging the picked items to protect them during transit. Proper packing ensures products reach customers in perfect condition and can include labeling and documentation for shipping.

Shipping:

This step involves dispatching the packed orders to customers through the chosen delivery method. Efficient shipping ensures timely delivery, tracking visibility, and a positive customer experience.

Returns Processing:

This step handles the return of products from customers, including inspection, restocking, or disposal. Efficient returns processing helps maintain customer satisfaction and keeps inventory accurate.

Importance of Efficient Order Fulfillment

-

Ensures timely and accurate delivery: Efficient fulfillment ensures customers receive the right products on time, reducing delays and errors.

-

Reduces operational errors and costs: Streamlined processes minimize mistakes, lowering returns, wasted resources, and extra shipping costs.

-

Improves inventory management: Accurate tracking and organization of stock prevent shortages, overstocking, and misplacements.

-

Supports scalability and growth: Efficient systems allow businesses to handle increased order volumes without compromising service quality.

-

Strengthens supply chain efficiency: Smooth coordination between warehouses, suppliers, and logistics partners improves overall workflow.

-

Provides competitive advantage: Fast, reliable, and accurate fulfillment differentiates a business in markets with high customer expectations.

Common Challenges in Order Fulfillment

Order fulfillment can be complex, and businesses often face several challenges that impact efficiency and customer satisfaction. Some common issues include:

-

Inventory Inaccuracies: Mismanaged stock can lead to overstocking, stockouts, or incorrect shipments.

-

Order Errors: Mistakes in picking, packing, or labeling can result in wrong or damaged products reaching customers.

-

Shipping Delays: Inefficient logistics, carrier issues, or last-minute demand spikes can cause late deliveries.

-

High Operational Costs: Manual processes, returns handling, and inefficient workflows increase expenses.

-

Scalability Issues: Rapid growth or seasonal demand can strain fulfillment systems and staff.

-

Lack of Visibility: Limited tracking and real-time data make it difficult to monitor orders and respond to issues quickly.

-

Returns Management: Handling returns efficiently while maintaining inventory accuracy and customer satisfaction can be challenging.

Best Practices for Streamlined Order Fulfillment

-

Implement Real-Time Inventory Management: Use systems that track stock levels accurately to prevent stockouts and overstocking.

-

Automate Processes: Incorporate Warehouse Management Systems, barcode scanning, and automated picking to reduce errors and speed up operations.

-

Optimize Warehouse Layout: Arrange products for easy access and efficient picking to save time and reduce mistakes.

-

Standardize Order Processing: Create clear workflows for order verification, packing, and shipping to maintain consistency.

-

Leverage Data and Analytics: Use demand forecasting and performance metrics to improve planning and decision-making.

-

Enhance Shipping and Logistics: Partner with reliable carriers, offer multiple delivery options, and provide tracking visibility.

-

Efficient Returns Handling: Establish clear return policies, inspection procedures, and restocking processes to maintain customer satisfaction and inventory accuracy.

-

Focus on Customer Communication: Keep customers informed about order status, delays, or issues to build trust and satisfaction.

Order Fulfillment Models

Order fulfillment models define how businesses manage the process of storing, picking, packing, and delivering products to customers. Choosing the right model depends on factors like order volume, product type, customer expectations, and business scale. Common order fulfillment models include:

-

In-House Fulfillment: The company manages all warehousing, inventory, and shipping internally. Offers full control but requires significant resources.

-

Third-Party Logistics (3PL): Outsourcing fulfillment to specialized logistics providers. Reduces operational burden and scales easily.

-

Dropshipping: Products are shipped directly from the supplier to the customer without being stored in the company’s warehouse. Minimizes inventory risk but offers less control over delivery.

-

Hybrid Fulfillment: Combines multiple models, such as in-house fulfillment for core products and 3PL or dropshipping for others, balancing control and flexibility.

-

Omnichannel Fulfillment: Integrates orders from multiple sales channels—online, offline, and marketplaces—into a unified fulfillment process.

Future of Order Fulfillment

The future of order fulfillment is being shaped by rapid technological advancements and rising customer expectations for speed, accuracy, and convenience. Automation, robotics, and AI-driven systems are transforming warehouses with faster picking, real-time analytics, and predictive inventory management. These innovations help businesses reduce errors, optimize workflows, and scale efficiently in high-demand environments.

Additionally, trends like same-day delivery, micro-fulfillment centers, and hyperlocal logistics are gaining momentum as companies move closer to customers to shorten delivery times. Sustainability is also becoming a priority, with eco-friendly packaging, optimized transportation routes, and greener warehouse operations. As digital integration deepens and customer expectations evolve, the future of order fulfillment will prioritize agility, transparency, and seamless end-to-end experiences across all channels.

Conclusion

Efficient order fulfillment is essential for delivering accuracy, speed, and a seamless customer experience. As technology and customer expectations continue to evolve, businesses must adopt smarter processes, real-time visibility, and automation to stay competitive and resilient.

At Ethics Prosperity, the commitment remains focused on enabling efficient, agile, and customer-centric supply chain operations. By applying the right strategies and continuous innovation, businesses can strengthen performance, boost satisfaction, and achieve long-term growth.